Creality latest Recycle Models M1/R1 is launching soon

Recently, Creality released a proprietary 3D printing material recycling system on its English official website, including the M1 Filament Extruder and the R1 Shredder. This system is designed to reprocess waste generated during the 3D printing process and convert it back into usable filament, enabling material recycling.

A true desktop-level recycling attempt aimed at consumers

It is reported that the system has a maximum output capacity of 1 kg/h, with filament diameter tolerance controlled within ±0.05 mm. It is compatible with common engineering and general-grade 3D printing materials such as PLA, ABS, PETG, ASA, PA, PC, TPU, and PET.

At present, the official selling price and release date have not yet been announced. We also attempted to contact Creality, but as of the time of writing, no further response has been received. However, based on the available information, the system already exists as a physical device and is not just a concept—it is likely still undergoing further optimization.

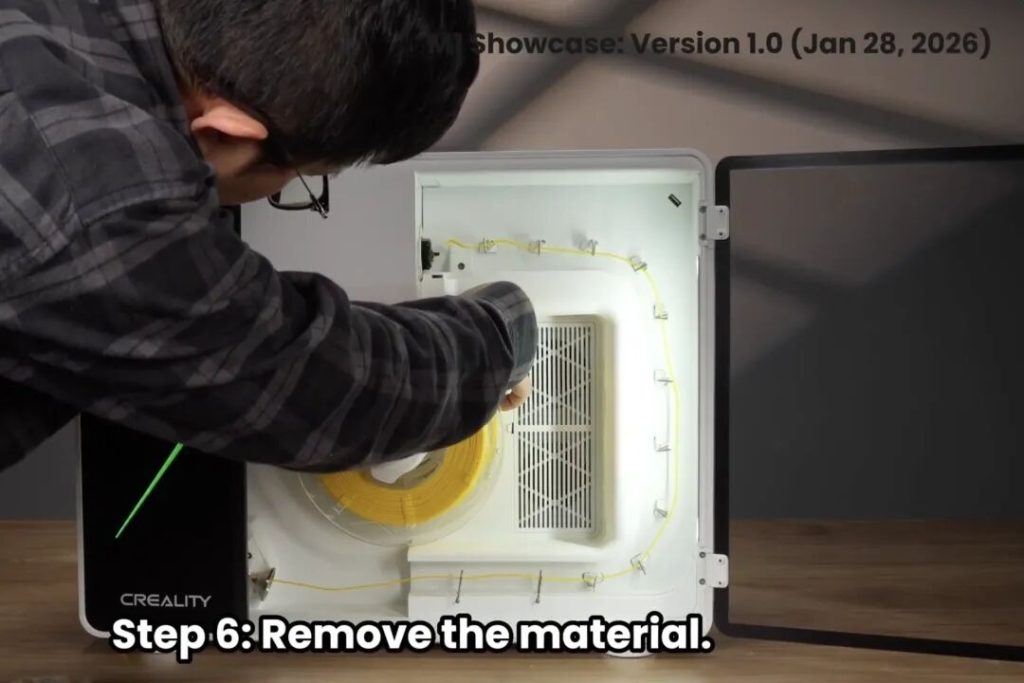

Layman terms for the workflow

The system consists of two machines: the R1 Shredder and the M1 Filament Extruder. Each unit stands approximately 560 mm in height, and when placed side by side, the total length reaches nearly one meter. In terms of overall size, it is slightly larger than the SPARKX i7 equipped with the CFS Lite.

Failed prints or support structures, and even waste from multi-color printing are firstly placed into the R1 to be shredded into small particles of about 4 mm in size.

Before moving to the next step, the particles are dried and then fed into the hopper of the M1. The material is then heated, melted, and re-extruded into filament. After being pulled through a guide rail and cooled, the filament is finally spooled.

Based on the demonstration video released so far, the entire process runs relatively smoothly. In addition to recycling waste, it also supports the addition of virgin pellets, natural fillers (such as coffee grounds), and even fragrances. With a bit of effort put into adjusting the ratios, creating rainbow gradient filaments is not difficult.

Looks simple, technically it is not EASY

However, turning recycled materials into reliably usable filament is no simple task. Looking back over the past decade, many enthusiasts have DIYed various filament extruders for 3D printing, but very few products have actually achieved commercial viability.

Among the products still commercially available today, the better-known ones come from the Netherlands-based company 3devo, which has launched two devices: the Filament Maker ONE and the Filament Maker TWO. Their respective prices are approximately €7K+ and €17K+ —clearly not aimed at the average consumer-level user.

In addition, a foreign company named LOOP previously claimed to have launched the world’s first desktop 3D printing filament manufacturing system. However, one year after the product announcement, a mature mass-production device has yet to be seen, and it remains at the launch video stage.

In contrast, there are also lower-cost DIY solutions. For example, Crestive 3DP offers the ExtrudeX, a complete set of STL files and part kits, with an overall cost of around $300. However, such solutions require a high level of hands-on skill and maintenance capability from the user.

Currently, the publicly available information is still limited, and we are quite looking forward to the official debut of this machine.

If its actual performance proves to be as stable and user-friendly as advertised, there should still be quite a few people willing to give it a try—especially those running 3D printing farms, who generate no small amount of waste every day.

Editor: LI Chen

E: lichen@3dzyk.com