This moment has been waiting over a decade: 3D printed shoes have finally reached the starting line of mass production.

In the past, most 3D printed shoes we saw were either high-end custom or limited-edition collaborations, and often only partially printed, such as the sole or upper. However, by 2025, products targeting the mass consumer market have become increasingly common. Industry giants including Nike and Adidas have launched fully 3D printed, one-piece shoes, heralding the footwear industry’s official entry into a new era.

If this summer, while walking down the street, you see someone wearing a pair of “full of holes” shoes with no laces, you might not be able to resist asking: “How do they feel?” Nine times out of ten, they’ll smile and reply: “Exceptionally comfortable and incredibly breathable—you should get a pair and try them yourself.”

From concept only to mass production, the turning point has arrived

With the maturation of materials technology, significant improvements in printing efficiency, and growing consumer demand for personalized products, 3D printed shoes are accelerating their move from the laboratory to the production line. Over the past decade, although fully 3D printed shoes frequently appeared in fashion shows and tech exhibitions, they never truly crossed the threshold of “mass production.” Now, that narrative is quietly being rewritten.

2025 is increasingly referred to by industry insiders as the “breakout year for 3D printed shoes.” Major sports brands have successively launched mass-produced, fully 3D printed shoe models, and even some startups are leading the industry. 3D printing is extending from the design stage to the delivery end, reshaping the entire production logic of the footwear industry. An era of intelligent manufacturing—without glue or stitching—is rapidly approaching.

Technology Maturity: Propelling the Industry into the “Mass Production Feasibility Phase”

The reason why full 3D printed shoes have achieved mass production lies in the continuous breakthrough of key technologies. Firstly, flexible materials have already passed market validation. For instance, dual-molecule elastomers exhibit high elasticity (250% elongation at break) and strong flex resistance (≥200,000 cycles), ensuring both the comfort and durability of printed shoes. Secondly, at the equipment level, ultra-high-speed light-curing technology has significantly improved printing efficiency, allowing a pair of shoes to be printed in less than one hour.

Furthermore, the “post-processing” bottleneck that 3D printed shoes once faced is now being gradually resolved by automated systems—from the automatic removal of support structures to integrated surface finishing processes. This enables printed products to quickly move into assembly or delivery, marking that 3D printed shoes have officially entered the era of batch production.

Brand recognition: Big players VS new players

As early as 2017, Adidas launched the Futurecraft series of running shoes based on Carbon technology, though only the sole was 3D printed at that time. By 2024, Adidas released its first fully 3D printed, single-piece shoe, ClimaCool. After repeated refinements and market testing, this shoe finally achieved mass production in 2025, marking a crucial step for Adidas in the field of full-shoe printing.

Meanwhile, Nike actually started experimenting with 3D printing even earlier. In 2013, they introduced their first 3D printed football shoe, the Vapor Laser Talon, which used SLS laser sintering technology to print the sole. Last year, Nike also launched its own fully 3D printed, single-piece shoe, the AIRMAX 1000, though it was limited to just 1,000 pairs, which is also related to the production capacity of its partner Zellerfeld—a point we will discuss further later.

Beyond Adidas and Nike, other international brands are also accelerating their follow-up efforts. For example, ASICS released the ACTIBREEZE series of 3D printed sandals, and PUMA unveiled the Mostro 3D printed sports shoe.

Domestic brands are equally unwilling to fall behind. Peak (Pike) began exploring 3D printing technology as early as 2012 and subsequently launched multiple limited-edition products. Currently, the available Phantom Colt 2.0 basketball shoe uses a 3D printed upper, while the FUTURE FUSION 5.0 incorporates 3D printing in the sole.

Even more noteworthy is the new brand STARAY, founded just in 2022, which has rapidly captured market share with its “Cells” series of 3D printed shoes. To date, its global cumulative sales have exceeded 120,000 pairs, demonstrating exceptionally impressive performance.

The value chain upgrade:Flexible manufacturing dominating the shoe industry

3D printing is quietly reshaping the footwear industry’s supply chain system. Compared to the traditional footwear industry’s massive investments in molds (often millions-level) and long production cycles, 3D printed shoes inherently offer the advantages of “zero inventory, on-demand production.” This flexible manufacturing capability allows brands to respond swiftly to market changes while reducing inventory costs and waste.

Clearly, brands and manufacturers are often separate entities in the industrial chain, so it’s necessary to shift our focus to the manufacturing companies that truly support the realization of 3D printed shoes.

Domestically, Suzhou Polly Technology is undoubtedly a key driver in this footwear manufacturing revolution. It is reported that over 80% of 3D printed footwear brands rely on Polly for production services, and its shipment volume of 3D printed shoes has long surpassed 1 million pairs. Currently, Polly 3D printing intelligent cloud factories have deployed 1,000 large-format HALS ultra-high-speed printing devices across multiple locations in China, achieving a production capacity of tens of thousands of pairs daily, making it the world’s largest 3D printed footwear production base.

Besides Polly, companies like Beijing LuxCreo and Guangdong Polytpe are also making continuous efforts in this field.

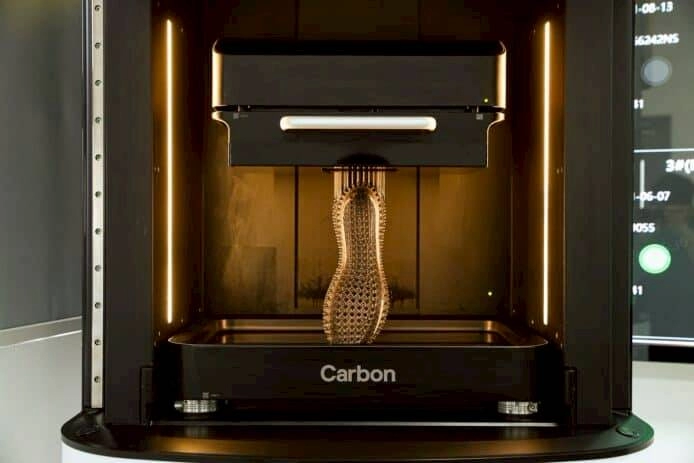

Internationally, U.S.-based Carbon is one of the most representative 3D printing technology providers for footwear. Based on its proprietary DLS (Digital Light Synthesis) technology, brands including Adidas and Puma have partnered with it. As full-shoe printing technology advances, Carbon is also progressing with its partner brands towards the next stage of fully 3D printed shoes.

A special mention must be made of Germany’s Zellerfeld. Unlike other mainstream 3D printed footwear manufacturers, they do not use light-curing technology but rather the more common FDM (Fused Deposition Modeling) printing method. Nike’s choice to collaborate with Zellerfeld significantly accelerated the latter’s development. Their number of printing devices is planned to expand from an initial 200 units to 5,000.

However, due to the inherent characteristics of the FDM process, the printing time for each pair of shoes often requires dozens of hours, so Zellerfeld still faces certain bottlenecks in production capacity. Nevertheless, it is foreseeable that with more devices put into operation, we can expect to see more AIRMAX 1000 shoes entering the public view.

It takes more time from Booming to Maturity

Although 2025 is considered as the breakout year for 3D printed shoes, the industry still faces practical challenges on its path to full maturity. The first is the cost issue. At present, large-scale 3D printing remains somewhat more expensive than traditional manufacturing processes. To achieve true substitution, further optimization is needed in equipment depreciation, material costs, and production efficiency.

Secondly, product consistency and standardization urgently need to be established. While the nature of 3D printing brings efficiency, it can also lead to quality variations. The industry requires unified testing standards, material specifications, and production certification processes to support long-term development.

Looking ahead, if technology continues to evolve, brands maintain their commitment, and prices become increasingly affordable over the next three years, it is projected that by 2028, 3D printed shoes will truly usher in their “year of popularization.”

And 2025 is the year of industrial awakening. 3D printed shoes are, right underfoot, reshaping the future.